- 메인으로 이동

- EEW KOREA

- Introduction of affiliated companies

- EEW GERMANY

Introduction of affiliated companies

Please see the future our company is pursuing in the EEW Korea website

EEW GERMANY

Founded in 1974

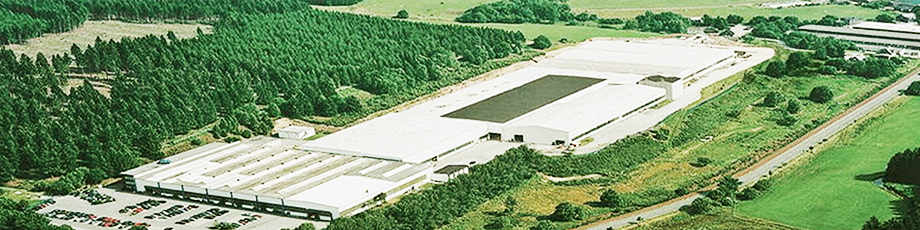

Located in Erndtebrucker, Germany

- Im Grünewald 2 57339 Erndtebrück Germany

- (+49) 27 53 609-0

- info@eew-group.com

EEW Germany, located in Erndtebrück

EEW in Germany - always one length ahead

Pipes made of the best steels which can be molten nowadays will be produced in the EEW fabrication lines.

From the arrival of the plates to the shipment of the EEW pipes everything moves on solid tracks. We are setting standards in the production of large pipes with our experienced staff as well as the most modern production lines for SAW pipes in the wall thickness range from 8 to 75 mm.

The speciality of EEW in Germany is the wide range of qualities. Carbon steel, low alloy steel, stainless and duplex/superduplex steel and high alloys are in our production programme.

EEW's ability: a very qualified team of engineers, a research and development department, motivated workers, combined with suitable professional machinery equipment.

Company information EEW Germany

Since 1974, EEW, a privately owned company, has been developing its activities in the SAW pipe business.

At the moment, no other pipe manufacturer is in a position to offer this kind of complete product range for the offshore, oil and gas process plant and steel construction industry.

Our 13.2 m (43') and 12.2 m (40') production lines guarantee an economical fabrication.

As a highlight, since 1995 EEW performs for the offshore industry Legs, Bracings and Sleeves for immediate assembly acc. to Point-to-Point procedure.

The total production capacity is 90,000 tons of carbon steel pipes and 15,000 tons of stainless steel (CRA) pipes per year.

With EEW products, our clients save investments, production and handling costs and time which is of great importance nowadays.

The 13 metre production line

The CNC controlled JCO forming press, optimized for high forming accuracy and efficiency is the heart of the production line.

The 12 metre production line

The 12 m production line, based on roll bending - completes the EEW programme. This line is specially designed for high efficient stainless steel pipe manufacturing.

SAW Technique

Submerged Arc Welding (SAW) is our standard welding procedure. Based on more than 30 years experience a welding technique up to 5 wires has been developed at EEW.